Production process

Cooper (Romania)

Cooper Industries

With Reijnen Sealing we don’t have only a supplier-customer relationship, but a partnership based on mutual interest and common values.

With Reijnen Sealing we don’t have only a supplier-customer relationship, but a partnership based on mutual interest and common values.

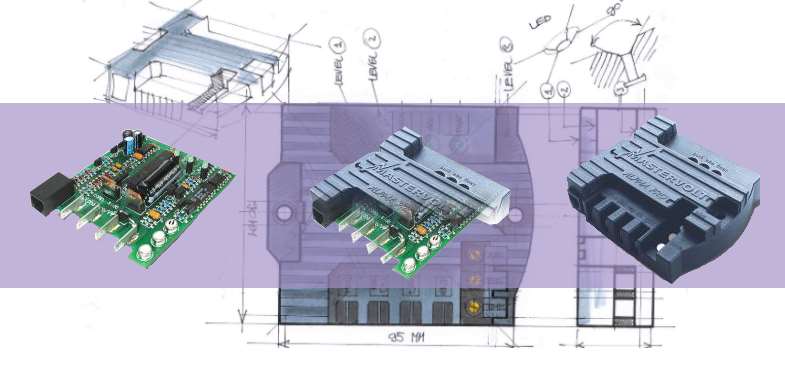

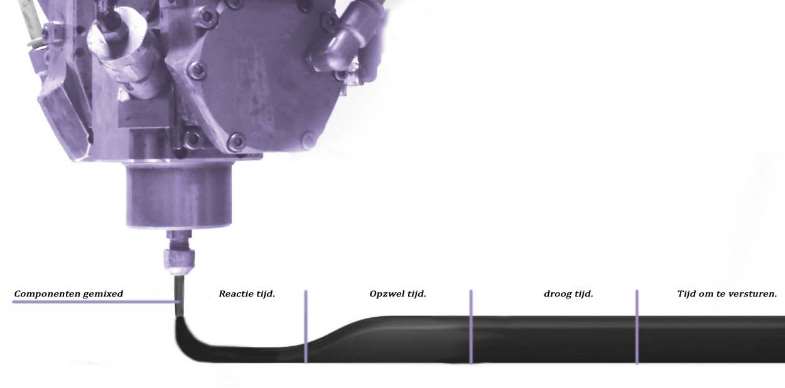

Production process

The products are checked and pre-treated if necessary before the robot applies the seal.

After a visual check the seal is applied to the product with a 2k dosage and blending system. The application of the seal calls for a high level of precision because the exact track on the products has to be kept to. The CNC controlled machines work with a precision of 1/100 mm.

All sorts of variables are also precisely configured, such as the hardness of the gasket, compression, form, and viscosity. Machines developed specifically for this purpose can be used to create a seal in any form.

For more information on this subject please see:

Contact

If you want to know if our techniques are suitable for your products or applications, please contact us! We are always willing to explore possibilities!

Contact

.png)

.png)